Small Scale, Big Impact

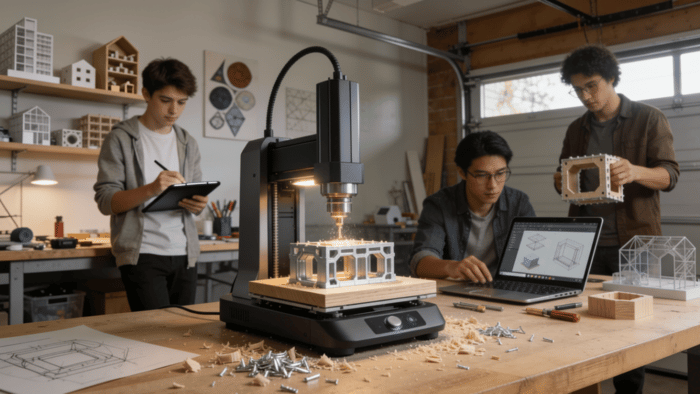

The future of making things is no longer reserved for large workshops or industrial floors. A quiet shift is taking place inside classrooms, design studios, and garages, where compact digital tools are transforming the language of creation. Among these, the Fabbot desktop router is becoming part of a new generation of accessible fabrication equipment that challenges assumptions about scale, cost, and who gets to build with precision. This movement is not about hype but changing behaviors—how people approach designing, prototyping, and producing functional products on demand.

We are seeing a reversal of the old rule that high-quality manufacturing must happen far away, behind barriers of capital investment and specialized training. Instead, digital fabrication is planting roots in unlikely places. Educators use these machines as teaching tools, independent designers shape their prototypes overnight, and communities experiment with shared-making spaces. It suggests a shift in what craftsmanship means when precision tools operate at a scale once considered impractical.

Shrinking the Scale Expanding the Possibilities

The heart of this change lies in reducing barriers. When a machine that once demanded a large workshop footprint can now fit on a desk, the psychological and practical impact is substantial. Designing a structural part or shaping a custom fixture is not limited to industrial operators. The maker, the student, and the professional can all engage with the same tool. This access is not just technical—it redefines participation.

More strikingly, the shrinking form factor does not mean shrinking capability. Compact routers process durable materials with accuracy, allowing creative experimentation without compromise. Whether building architectural models, functional enclosures, or experimental art pieces, designers are learning that smaller tools can still deliver industrial-grade outcomes. This recalibration gives innovators the confidence to think differently about their workflow.

The Culture of Prototyping

Once, a prototype was a costly intermediate stage. It meant sending files elsewhere, waiting for processing, and testing only when the finished model returned. Now, the process has shifted into daily iteration. With desktop tools, creators iterate in real time, adjusting designs, testing fits, and moving forward in rapid cycles. This habitual prototyping changes not just the speed of development but also the mindset. Risk becomes easier to manage, and exploration feels natural rather than expensive.

In this cultural change, the Fabbot desktop router is both a teaching tool and a professional instrument. It translates theory into tactile experience for learners, balancing the abstract with the concrete. For skilled operators, it compresses the time between concept and outcome. What results is a form of democratization—an environment where making is not distant but immediate.

Beyond Function into Expression

As accessible as they are functional, compact fabrication tools are fostering a blend of engineering and artistry. While precision routers can produce strong mechanical parts, they also enable intricate designs, fine detailing, and even decorative elements that combine beauty with utility. This blurred line between functional object and creative statement opens opportunities in design fields that benefit from both.

When creators have hands-on access to their tools, they embed personal character in their work. The ability to physically shape and experiment adds a dimension no screen-based model can capture. The result is a renewed appreciation of materials, techniques, and process. What once felt distant becomes tactile, immediate, and personal.

Redefining Accessibility in Making

Accessibility is more than affordability; it is also about time, space, and confidence. Compact routers lower the intimidation factor. Instead of complex, warehouse-scale setups, users encounter interfaces and operations designed for direct engagement. This shift has less to do with hobbyism and more with breaking unnecessary boundaries between idea and execution.

Small machines can have a big impact when they offer independence. A designer without access to a factory can still create functional components. A classroom without industrial infrastructure can still provide practical fabrication skills. An entrepreneur can move from thoughts to tangible prototypes without leaving the workspace. Each of these represents a significant decentering of manufacturing power.

Precision, desk-scale routers illustrate how definitions of crafting and building are expanding. They remind us that innovation thrives in large facilities and small, shared environments where people use tools directly. As more compact machines evolve, the conversation around making will shift from exclusivity to inclusivity. That transition may not carry dramatic slogans, but it carries real potential—a slow but steady rewriting of how we shape the objects that shape our daily lives.