Revolutionizing Meat Packing with Smart Sensors

What if the next steak on your grill came with an invisible shield—tiny tech sentinels watching over it from slaughterhouse to supermarket? In the high-stakes world of meat packing, smart sensors are flipping the script on food safety, turning potential disasters into seamless precision and putting fresher cuts on your plate with less waste and worry.

The Vulnerabilities of Traditional Methods

Traditional meat packing hinges on manual vigilance: thermometers plunged into coolers, line workers eyeing cuts, and logbooks filled by hand. These methods work hard but falter fast—a momentary door swing or machine hiccup can spike temperatures, inviting bacteria like Listeria or E. coli to take hold. The fallout? Spoilage losses are hitting 10-20% in some plants, and recalls are shaking consumer confidence and driving up prices. From my vantage, these blind spots burden everyone, from floor supervisors to home cooks scanning labels.

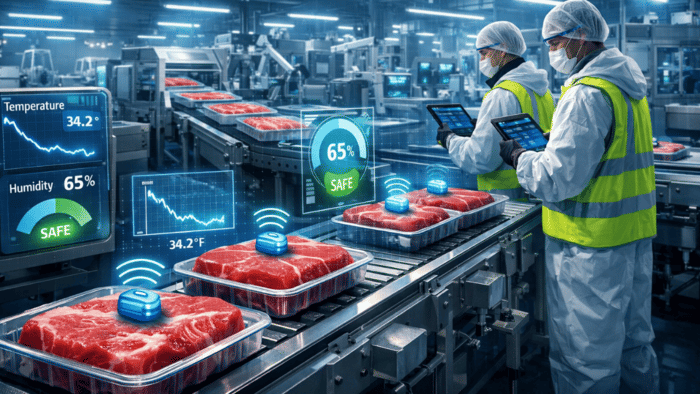

The Role of Smart Sensors

Smart sensors—compact, resilient units scattered across the production floor—track temperature, humidity, and spoilage gases nonstop, beaming data via IoT to central dashboards. Here, meat temperature sensors take center stage, probing deep into carcasses to catch unsafe warming early and stop bacterial blooms in their tracks. Built with tough, chemical-resistant materials, they endure the plant’s rigors while AI layers predict trouble, as spoilage from sudden humidity jumps.

Tangible Improvements in Operations

Post-slaughter chilling gets a boost as sensors swiftly lock in sub-40°F drops, halving the odds of contamination. Grinding lines stay cool under sensor watch, dodging defects that scrap whole runs. In transit, GPS-tied devices flag truck reefer slips, enabling quick fixes. Plants using these report 30% less waste, with color-shifting package tags that instantly spotlight bad lots. The ripple? Smoother supply chains, stable pricing, and that ribeye hitting your table reliably safe.

Overcoming Implementation Hurdles

Rollouts face real friction: steep startup costs for sensor webs test small operators, and data floods call for trained eyes on analytics. Cyber risks to food networks demand ironclad defenses. Yet, with sensor prices now pocket-friendly at volume and regs like HACCP pushing harder, momentum builds. Savvy facilities harness machine learning for hands-off tweaks, like auto-adjusting chillers, turning hurdles into high returns.

Toward a More Reliable Food Chain

These tools don’t just upgrade plants—they rebuild trust package by package. Horizons gleam with pathogen-sniffing biosensors and blockchain trails from farm to fork. Having followed food tech’s arc, I see smart sensors as the bridge from gritty production to everyday peace of mind. Meat packing’s quiet revolution is here, serving up safer, smarter meals for us all.